Enclosed die forging of an automobile differential’s bevel gear – Post 2/2

페이지 정보

작성일posted onLink

본문

Enclosed

die forging of an automobile differential’s bevel gear – Post 2/2

This article is a continuation to the earlier article - http://www.afdex.com/archive/blog/4

In this

article, we will go further into the results and discuss this approach from a

manufacturing perspective.

Just a recap of the important information.

The

material of the bevel gear is SCM420H and a saw-cut circular bar (radius 17.5

mm x height 39.0 mm) was used as the

initial shape of the material.

Contact

limits of die and material: 0.05 mm;

About

80,000 tetrahedral elements were used;

Die

speeds of the second stage: -1.0 mm/s (upper die), 0.0 mm/s (lower die).

A

constant shear stress friction was used as the friction condition for the

analysis.

The

friction coefficient of the upper die to produce the tooth profile was assumed

to be 0.2.

The

friction constant of the remaining dies was assumed to be 0.1.

The

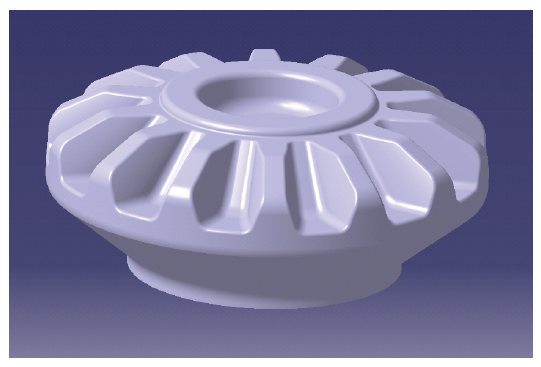

selected target product is the bevel gear for the differential of a vehicle, as

shown in Figure 1.

Figure 1. Bevel Gear CAD Model

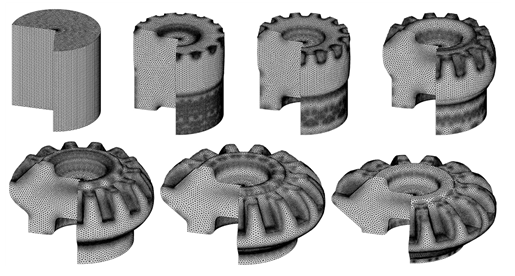

Figure 2 shows the FE predictions of deformation obtained using AFDEX.

Figure 2. FE prediction of deformation

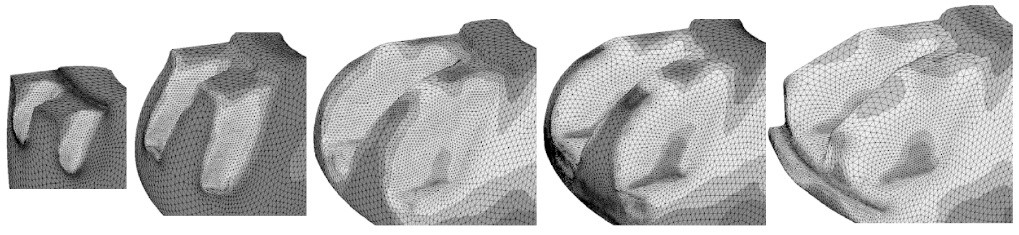

Figure 3. Predictions of tooth profile and effective strain contours

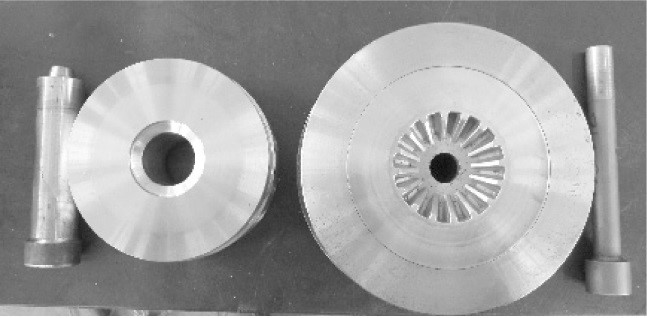

Figure 4.

Die making process (Courtesy: Jin Eng.)

The preparation of workpiece material in closed forging is also very important. Since the shape of the workpiece changes massively during closed forging, the material must be softened through a spheroidizing annealing process. If the annealing temperature is not set properly, cracks may occur in the closed forged product.

Shot peening is applied to the un-coated raw material to remove

scales, decarbonized layers and foreign substances on the surface.

For the

purpose of pilot production, the hydraulic press shown in Figure. 5 (a) and the

closing die set shown in Figure 5 (b) of Gyeongsang National University TIC was

used. This hydraulic press has specifications such as pressure capacity of

10000 kN and stroke length of 600 mm.

Figure 5.

Hydraulic press used for this process

Figure 6 shows the test results of the closed forging of a bevel gear produced using the above-mentioned die and equipment, and shows the deformation history of the work piece material during the forging process. As a result of the visual inspection, defective elements such as defect of lubricating film, breakage in forming state, folding, cracking, and scratching did not occur. The single pitch error, the adjacent pitch error, the cumulative pitch error, and the shaking of the groove was also checked using a bevel gear tooth tester.

Figure 6. Closed forging experiment results of bevel gear

Quality assurance is very important in commercial development of economical bevel gears. It is essential that repetitive fabrication of the same die should be supported. The production method and the process design must be robust and efficient.

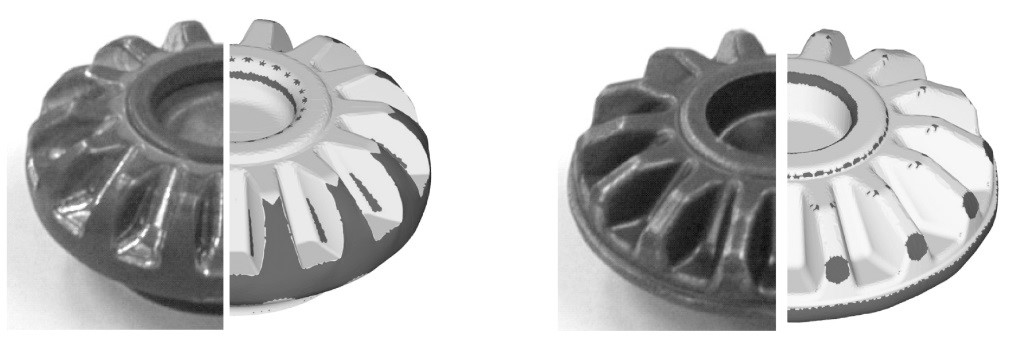

Figures

2 and 6 show that the experimental and analytical results are very

similar. That is, as a result of comparing according to the stroke distance of

the upper and lower punches, the shape of the material entering the die and the

shape of the tooth profile are very similar. In the comparison of Figure 7 (a)

and Figure 7 (b), the predicted and experimental results agree very well.

Figure 7 (a, b). Comparison of

prediction and experimental results - Forging(Left) & Sizing(Right)

Do follow us on LinkedIn to stay updated and know more interesting simulation examples from a wide variety of metal forming processes.