Quality indices of metal flow lines

페이지 정보

작성일posted onLink

본문

The metal flow (grain flow) lines have a significant effect on the life of the forged product. According to research (Ito et al.), the tests on tapered roller bearings indicated that products with good metal flow lines have up to 6 times longer life than products with non-optimized ones. It has been well known (Refer to the conference book of MFCAE 1996, edited by M. S. Joun or AFDEX homepage) that SKF strictly require the symmetry of the first-generation hub bearing outer race.

Until now, there was no other way to determine the quality of metal flow lines. This problem has been a great obstacle to optimize the design of the metal forming process design using a metal forming simulator. In other words, when defining the process design optimization problem, it was not possible to treat metal flow lines directly as an objective function or constraint.

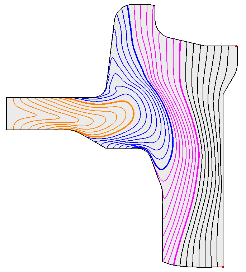

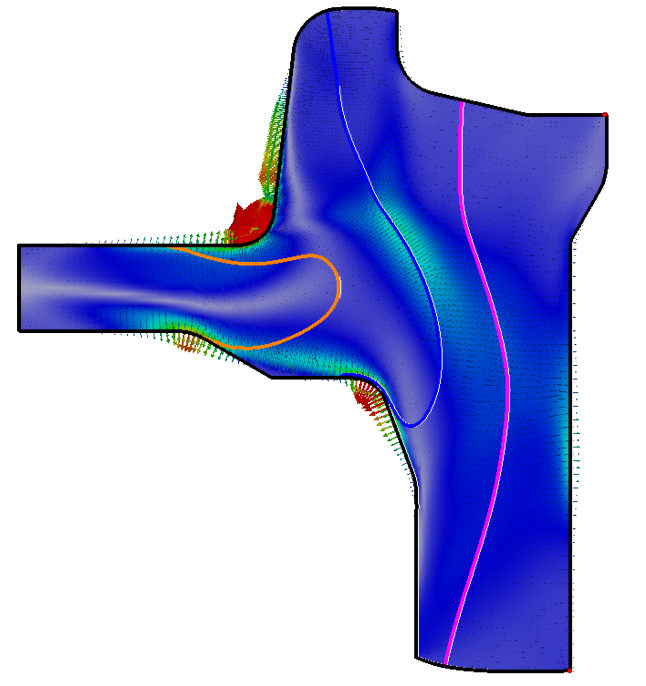

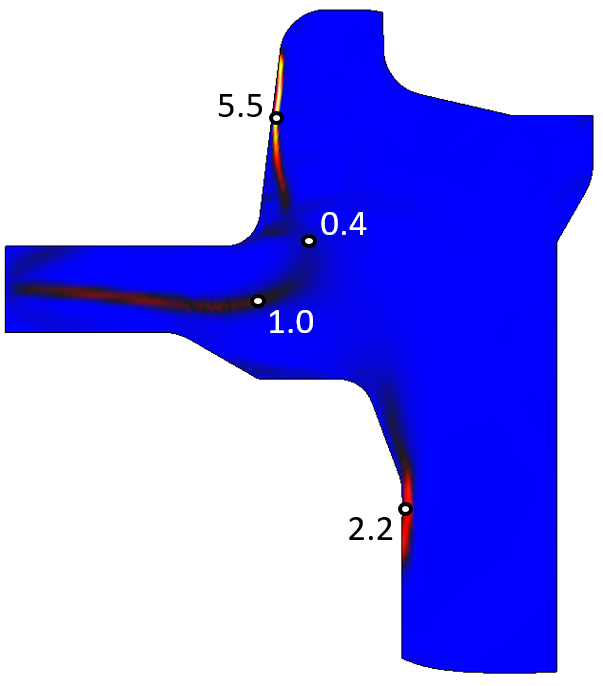

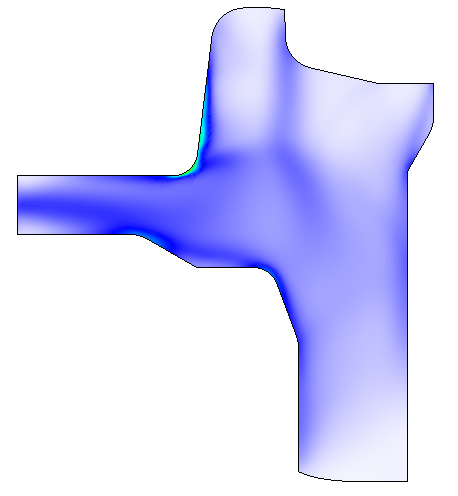

Recently, the quality indices of these metal flow lines have been developed, including the density function of metal flow lines and its overlapping index. Fig. shows the application examples. Fig. shows that the possibility of overlapping was well described by the overlapping index recently developed for AFDEX. However, comparison of Fig. (c) with Fig. (d) shows no similarity between the overlapping index and effective strain, emphasizing the importance of the index.

Note that overlapping of the metal flow lines can be prevented by minimizing or controlling this index. The same approach applies to both 2D and 3D.

|

|

(a) Metal flow lines | (b) Density function |

| |

(c) Overlapping index | (d) Effective strain |

Fig. Metal flow lines and quality indices