Most contributed industry – Bearing industry

페이지 정보

작성일posted onLink

본문

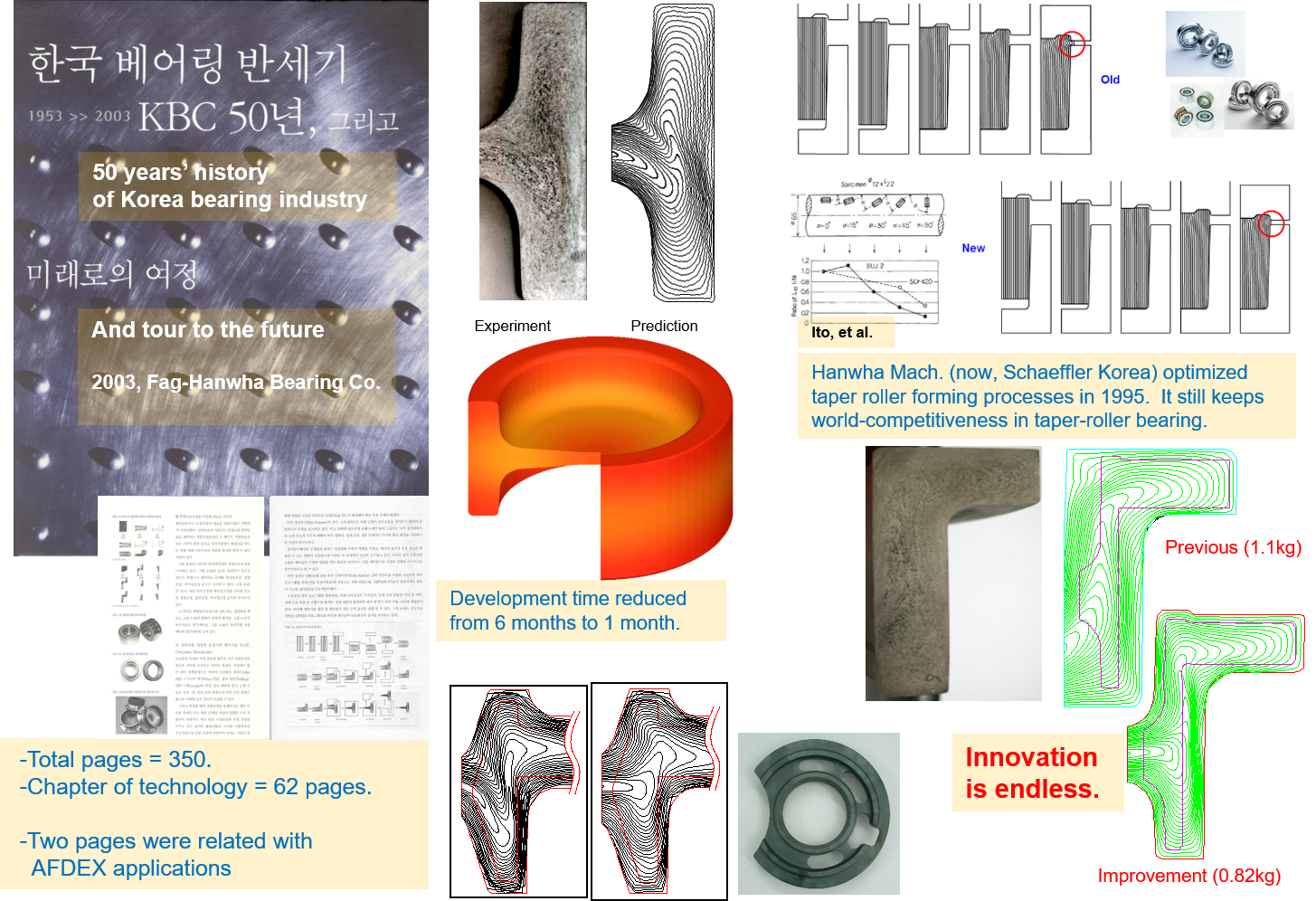

One of the industries where AFDEX was successfully and more often applied was the Korean bearing industry. In 2003, Fag-Hanwha Bearing Co., (Currently Schaeffler Korea) published a book titled “50 years history of Korean bearing industry” where AFDEX occupied two among 62 pages dedicated to the technology sector, owing to the value added by AFDEX in a very short time since its inception.

Some examples from the bearing industry are summarized here. The taper roller forming process was optimized using AFDEX and this optimized process contributed to company’s current global competitiveness in the taper roller bearing business. They could also optimize the steel ball forming process, saving 6% of the manufacturing costs.

Fag-Hanwha Bearing Co was also successful in applying AFDEX to optimize the metal flow lines of the first-generation hub bearing outer race as shown in the figure above. They could reduce the development time from a minimum of six months to just one month. The process design try-outs were excluded from their part development procedures, which is very costly and time-consuming. AFDEX innovated the traditional forging process design in Korea.

Prior to the introduction of AFDEX in 1996 to the Korean bearing companies, most of the forging processes were imported from industrialized countries like Japan and Germany. Thanks to the forging simulation technology through AFDEX, this trend changed, and major Korean forging companies could become independent forging process designers. Of course, AFDEX has always been the most convenient and easy-to-use forging simulator and therefore even forging engineers and technicians working for small-sized Korean companies started using it with ease.