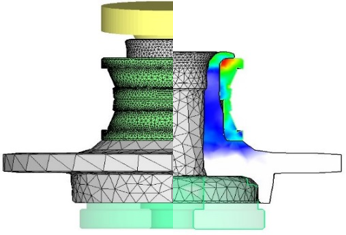

Elastoplastic finite element analysis of assembly process of hub bearing assembly

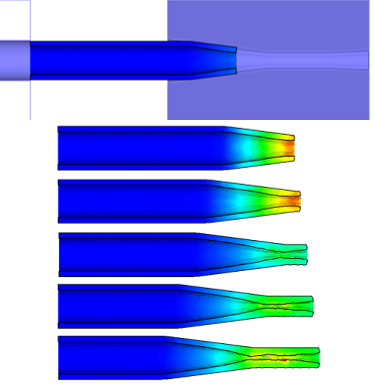

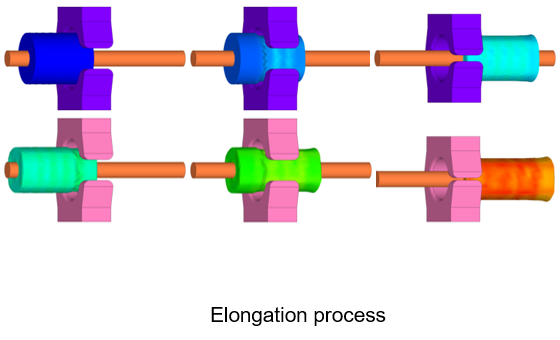

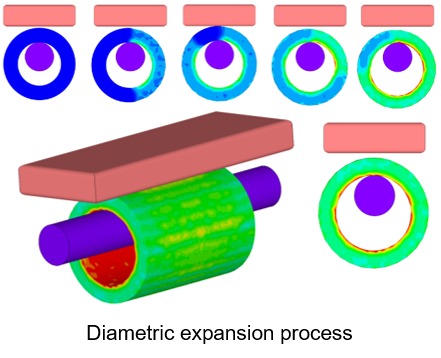

The assembling process of the hub bearing assembly and the rotary forging process using the three-dimensional elastoplastic finite element analysis function was carried out. The bearing was assumed to be an elastic body. Above figure shows the residual stress.

Read MoreHammer open-die forging

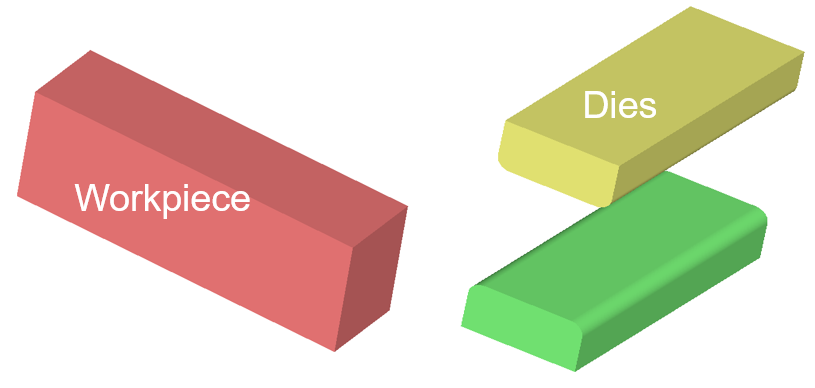

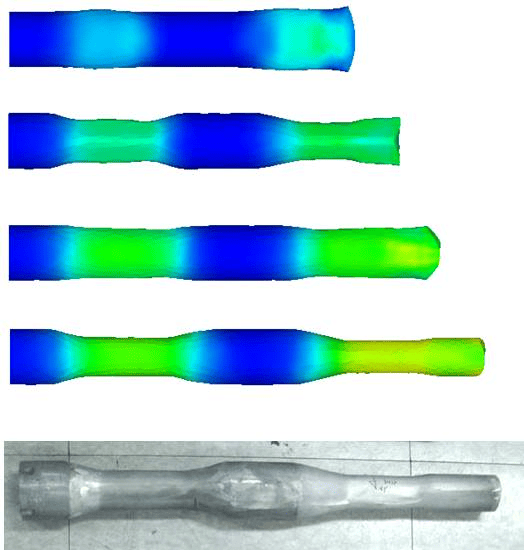

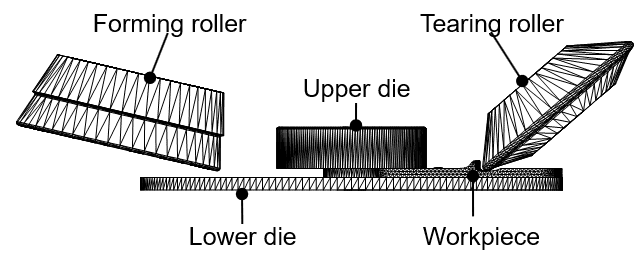

■ Concept of hammer open-die forging simulation ● Process description ◾ Information about materialS55C(T=800-1300℃)Geometry: See the figuresInitial temperature: 1200℃ ◾ Information about diesGeometry: See the figuresFriction:Coulomb friction(μ=0.2)Die velocity: Hammer press type ● Process information 1 2 3 4 5 6 7 8 9 10 11 12 Striking strength 0.2 0.2 0.1 0.5 0.3 0.4 0.7…

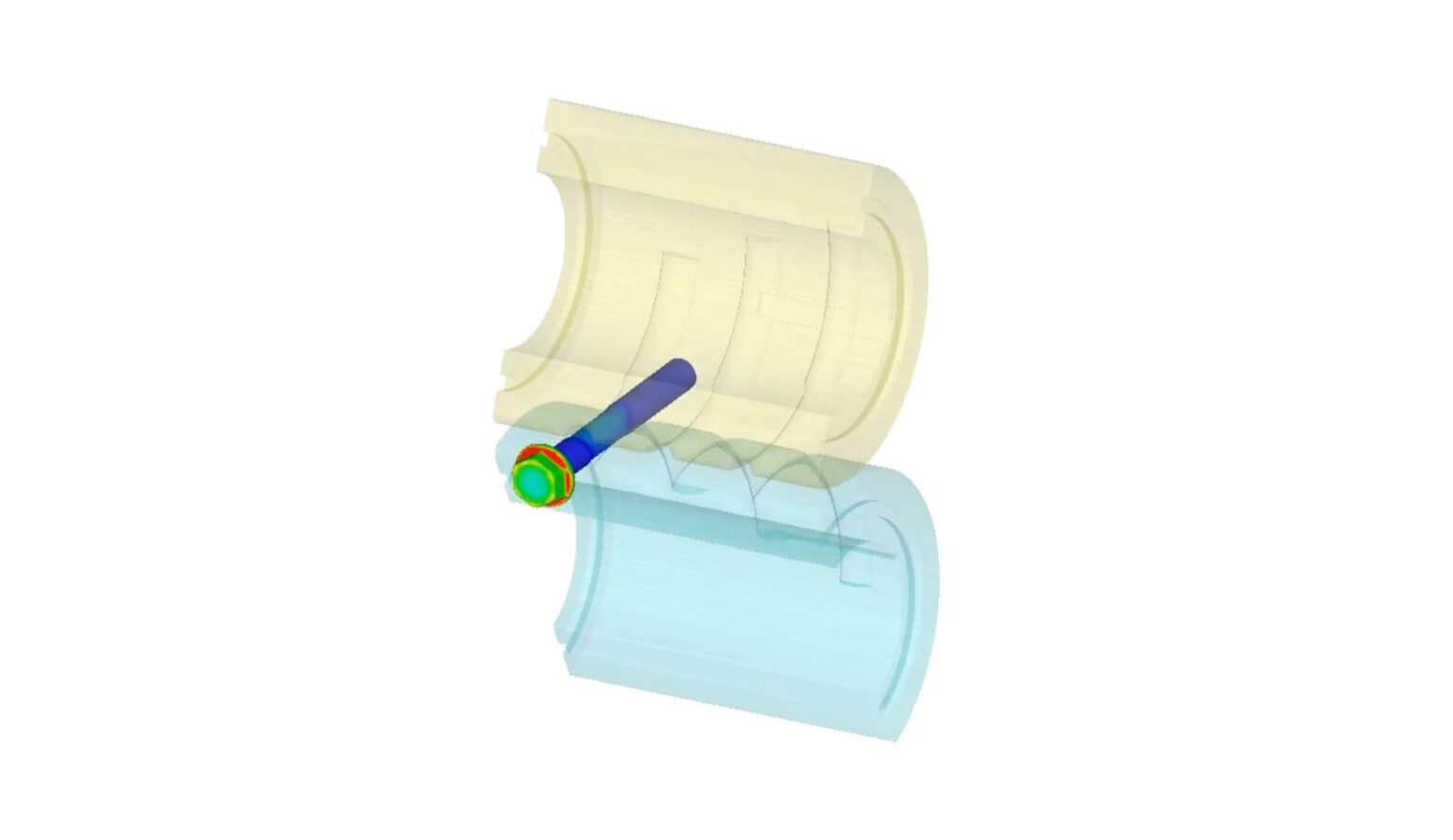

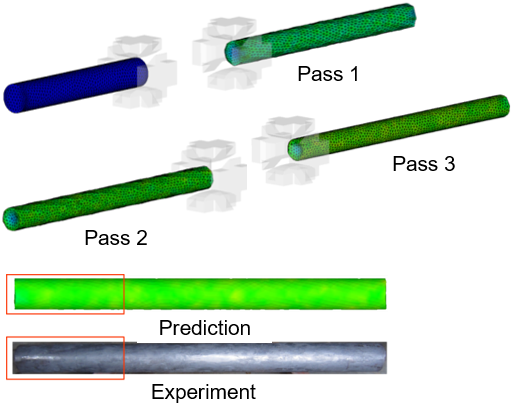

Read MoreNew grip model

Recently a grip model for roll forging was improved. With the new grip model, we can apply pulling force to the material, which is proportional to the roll separating force. Of course, The maximum pulling force by some limited value given by users can be constrained. With this model, more stable and accurate predictions could…

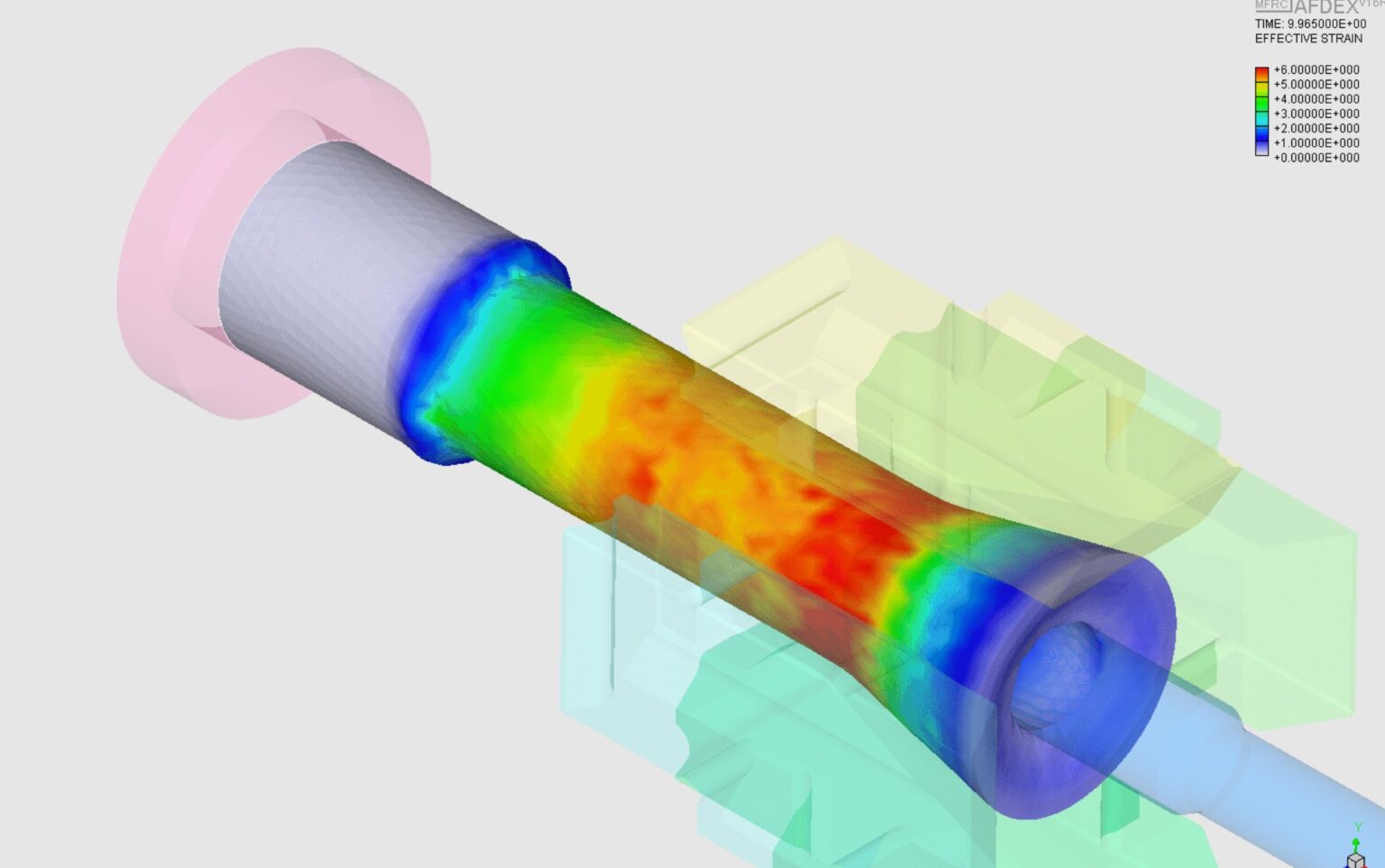

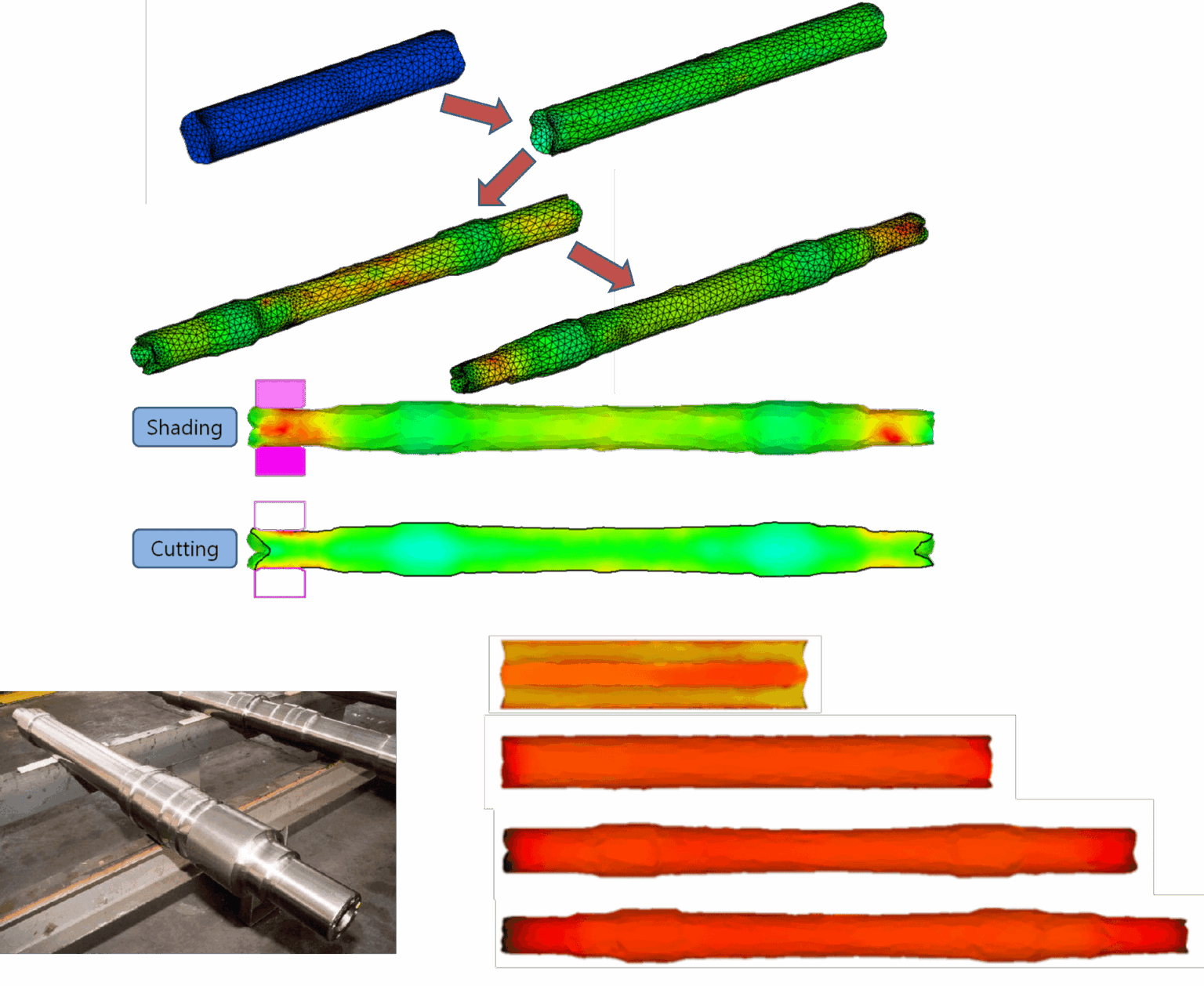

Read MoreSpacial warm radial forging process

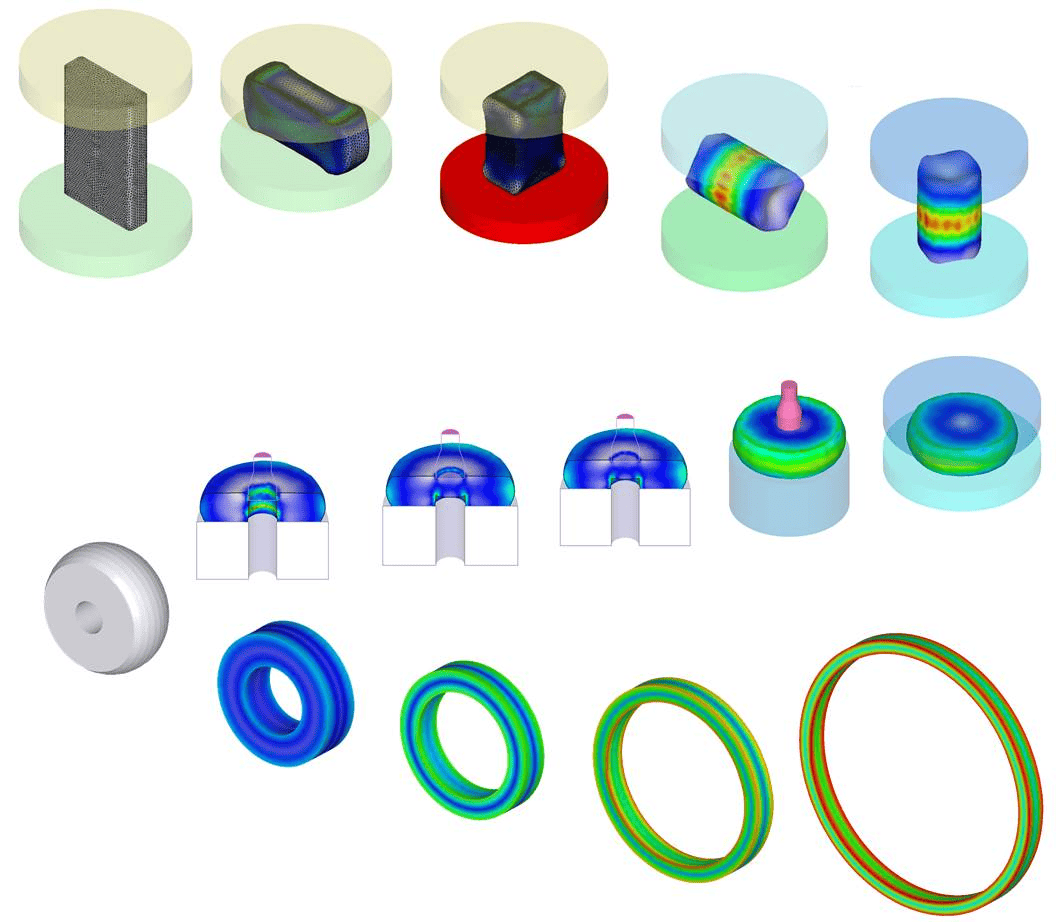

The spacial warm radial forging process of Hyundai WIA for fabricating a hollow shaft auto-part was shown in these figures. The metal flow lines inside which are in good agreement with experiments, as shown in these figures, was predicted by special function in AFDEX.

Read More