Master of Masters

AFDEX- Intelligent Forging Simulation

Software for Metal Forming

Master Metal Forming with AFDEX

Faster, Easier, and More Accurate!

AFDEX (Adviser for Metal Forming process Design EXpert) is an high-accuracy and user-friendly forging simulation software designed to help manufacturers optimize their cold forming, hot forming, extrusion, drawing, ring rolling, plate forging, sheet metal forming, and other metal forming processes with unmatched accuracy and efficiency.

With its intuitive user interface and high-precision simulation technology, AFDEX empowers engineers to minimize defects, enhance product quality, and maximize manufacturing efficiency.

Optimized for Multi-Stage Forming

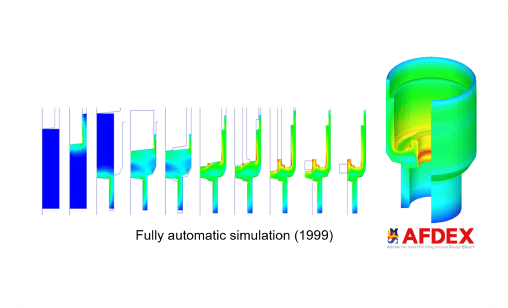

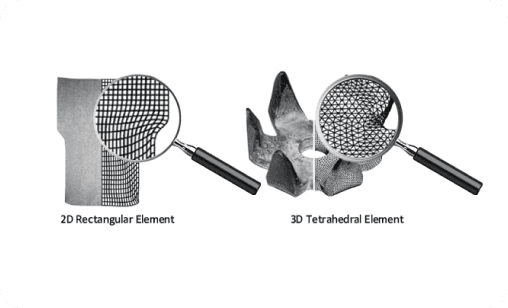

AFDEX is a forging simulation software specifically optimized for automatic multi-stage cold or hot forging processes. It is designed to be easily accessible, even for users who are new to the simulation software.

Developed based on practical forging expertise and advanced engineering principles, AFDEX enables users to obtain high-precision simulation results with minimal effort, eliminating the need for complex configurations. Its intuitive interface allows beginners to perform accurate analyses with minimal user intervention, while also effectively supporting process design and optimization.

Reliable software for Manufacturing Excellence

For metal forming experts, accurate simulation results are essential. Low simulation reliability can lead to process errors and increased production costs.

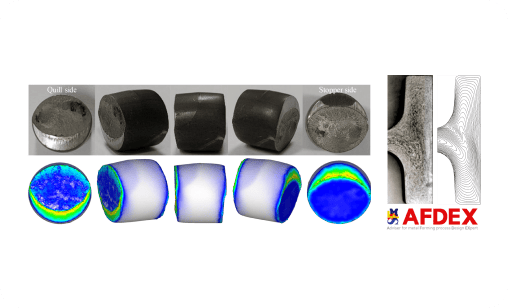

AFDEX delivers high-accuracy simulation results that closely replicate real-world manufacturing conditions, ensuring stable and efficient production.

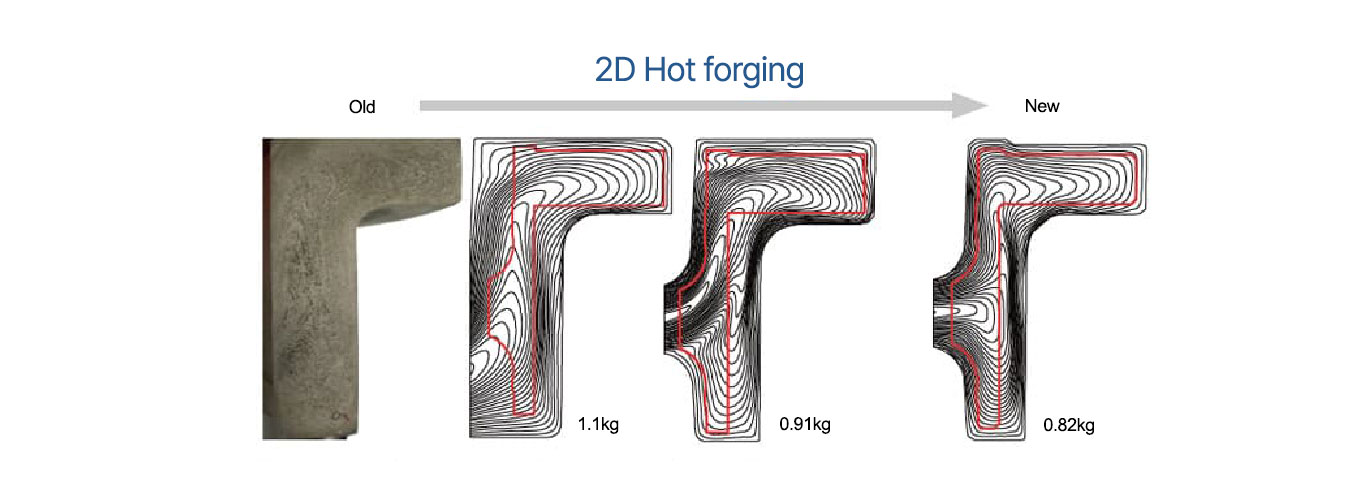

We continuously enhance AFDEX’s accuracy by integrating advanced technologies such as metal flow line analysis, material identification, adaptive meshing, remeshing, and more.

Improve process reliability and experience the most accurate metal forming simulation with AFDEX.

Enhancing Engineering Problem-Solving

AFDEX helps engineers develop independent problem-solving skills by combining real-world expertise with advanced simulation technology. When metal forming specialists integrate their field-based knowledge with simulation, they can predict defects and outcomes that physical experiments cannot reveal. This enhances creativity, technical intuition, and engineering decision-making.

Forge Ahead with AFDEX – Smarter Solutions, Faster Results!

Forge your future with AFDEX

Using AFDEX simulation software, you can shorten process development time,

reduce production costs, and improve product quality by predicting defects.

Do you have any questions

about metal forming simulations?

Send us your comment, question or suggestion, or make a request.

We'll be in touch as soon as we can.

Jinju, Gyeongsangnam-do, Republic of Korea, 52818

Copyright ⓒ 2025 MFRC Co., Ltd. All Rights Reserved