Die elastic deformation in hot forging by rigid-plastic finite element method

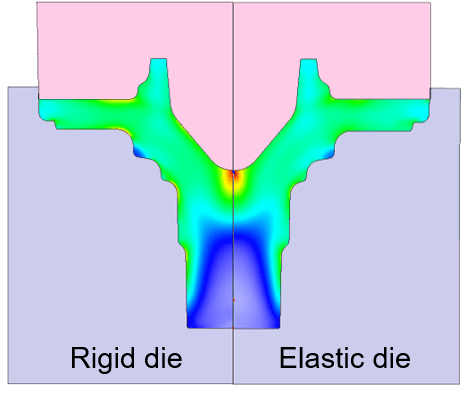

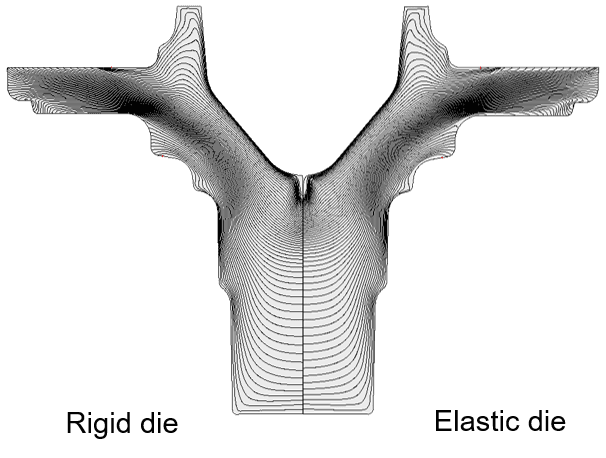

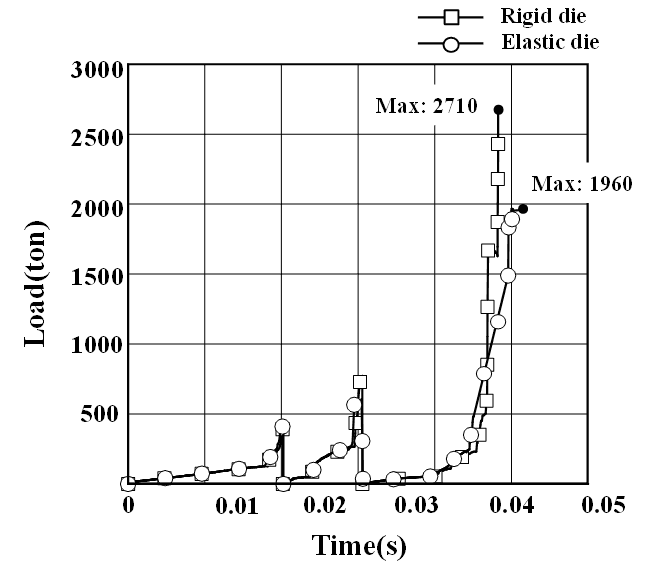

The figures compares the predictions of an axi-symmetric hot forging process between with and without considerations of die elastic deformation. The process does not allow any flash, that is, it is a flashless closed-die forging process.

Of course, grain flows of them are very close to each other. However, forming loads at the final stroke is quite different. Elastic deformation of die reduced the predicted forming load by almost 30%, compared with the rigid-die case. This is one of the reasons that predicted forming loads are considerably greater than the actual forming loads especially in closed-die forging without flash.

Do you have any questions

about metal forming simulations?

Send us your comment, question or suggestion, or make a request.

We'll be in touch as soon as we can.

Jinju, Gyeongsangnam-do, Republic of Korea, 52818

Copyright ⓒ 2025 MFRC Co., Ltd. All Rights Reserved