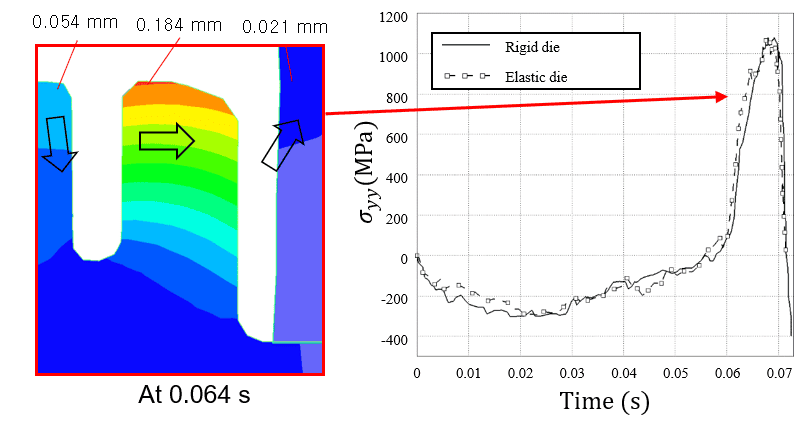

Simulation considering die deformation

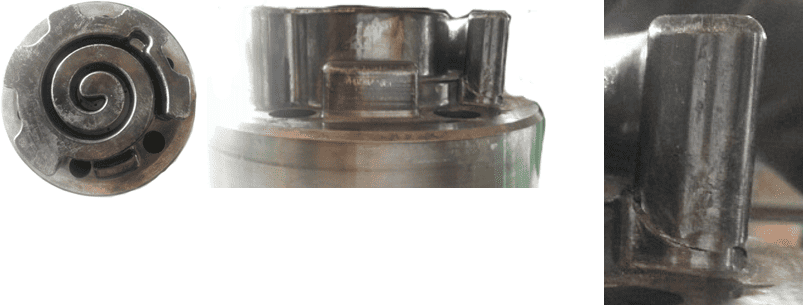

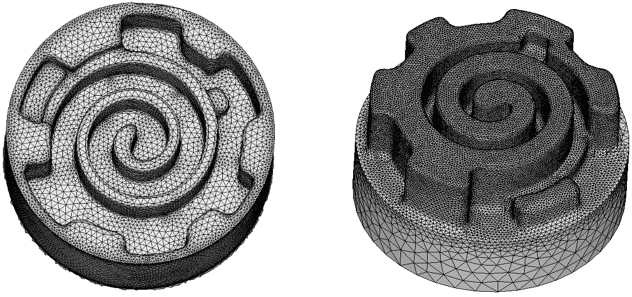

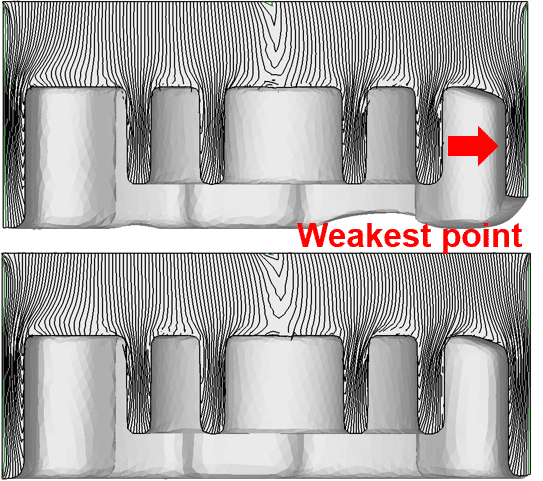

This figures simulated a scroll forging process under rigid-die or elastic-die assumptions to reveal the die fracture occurring at the root of wrap.

The major reason of the fracture lies in the unbalanced filling of material between the wraps. As a whole the effect of the elastic-die is negligible.

From more detailed observation, however, we can find that a little earlier fracture occurred for the elastic-die. From this figure, the width increase of the die cavity in the left side is a little greater than that of the right side, which caused the difference in fracture time.

– Fractured die –

– Mesh System –

– Metal flow line –

– Effective strain –

– Distribution of σyy –

– Die displacement | Stress component σyy –

KSTP Autumn 2014 / KSTP Spring 2015 / KSTP Fall 2016

Do you have any questions

about metal forming simulations?

Send us your comment, question or suggestion, or make a request.

We'll be in touch as soon as we can.

Jinju, Gyeongsangnam-do, Republic of Korea, 52818

Copyright ⓒ 2025 MFRC Co., Ltd. All Rights Reserved