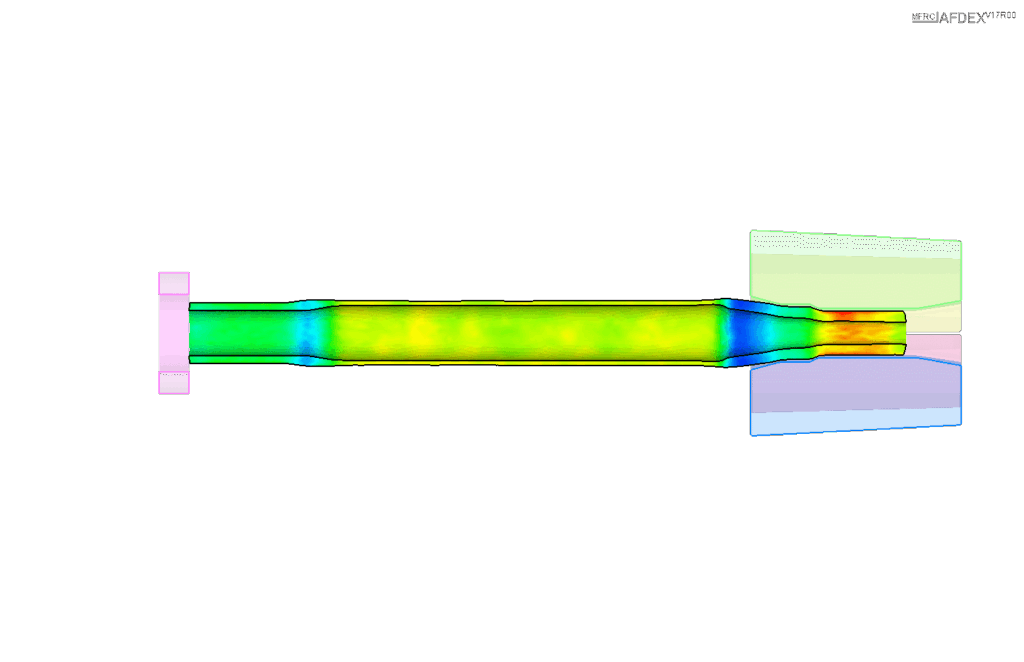

Analysis of multi-stage hollow shaft swaging process

An analysis of the 5-stage hollow shaft swaging process was made. In this process, the change of the thickness is very high in the first and second stages. The position of the workpiece is controlled by the mandrel in the first and second stages and pusher controlled the workpiece motion in the third stage. Above figure shows the final deformed workpiece and the process consisted of totally 5310 blows.

Do you have any questions

about metal forming simulations?

Send us your comment, question or suggestion, or make a request.

We'll be in touch as soon as we can.

Jinju, Gyeongsangnam-do, Republic of Korea, 52818

Copyright ⓒ 2025 MFRC Co., Ltd. All Rights Reserved