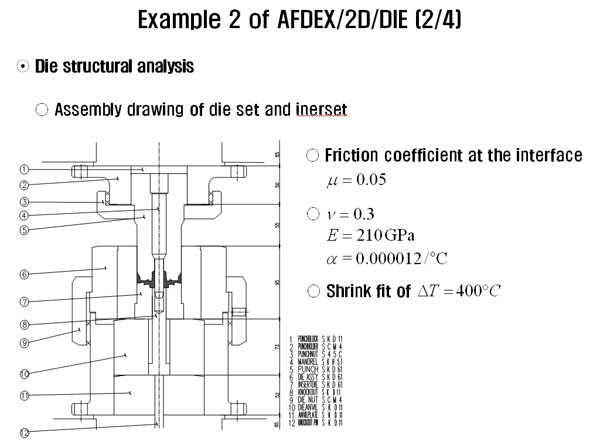

Example 2 of AFDEX/2D/DIE (2/4)

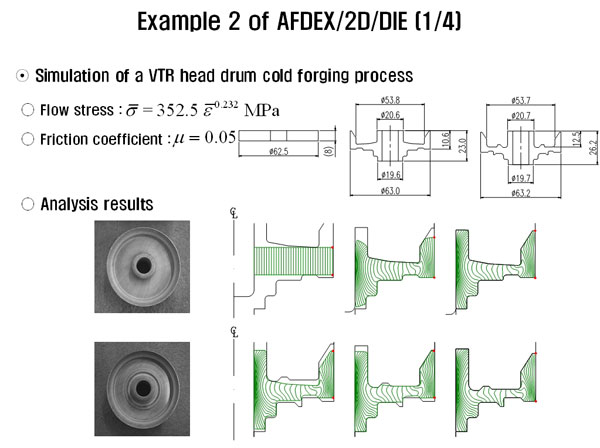

Example 2 of AFDEX/2D/DIE (1/4)

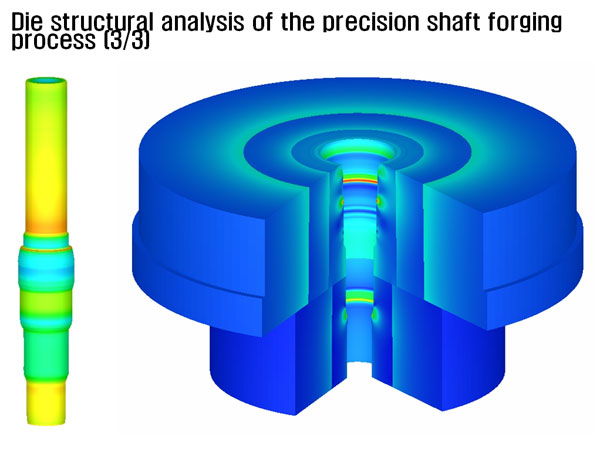

Die structural analysis of the precision shaft forging process (3/3)

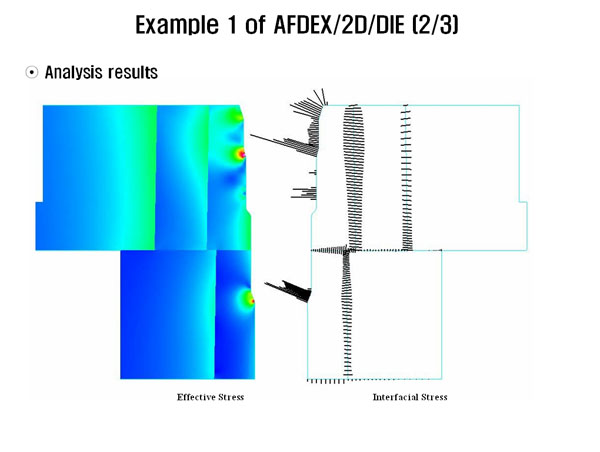

Example 1 of AFDEX/2D/DIE (2/3)

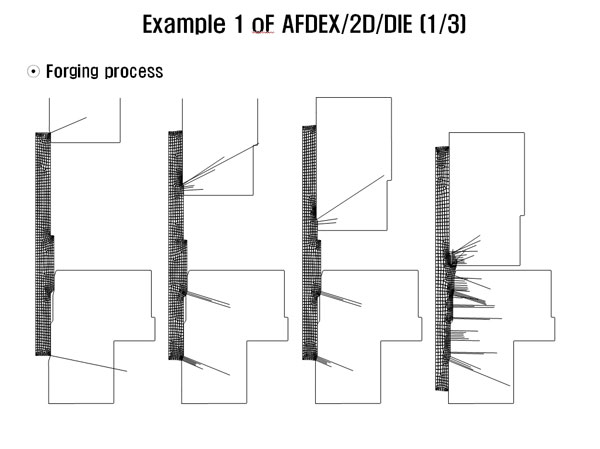

Example 1 oF AFDEX/2D/DIE (1/3)

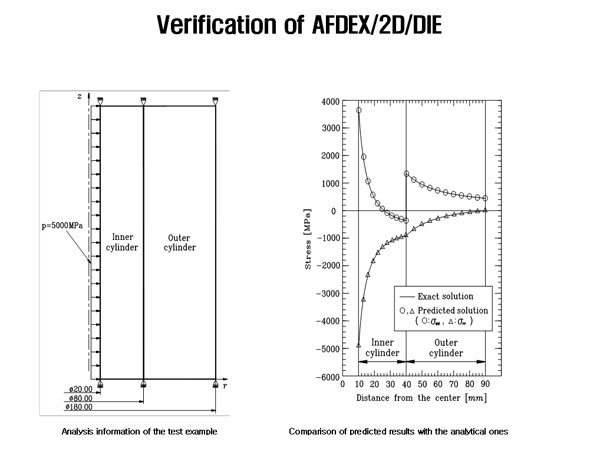

Verification of AFDEX/2D/DIE

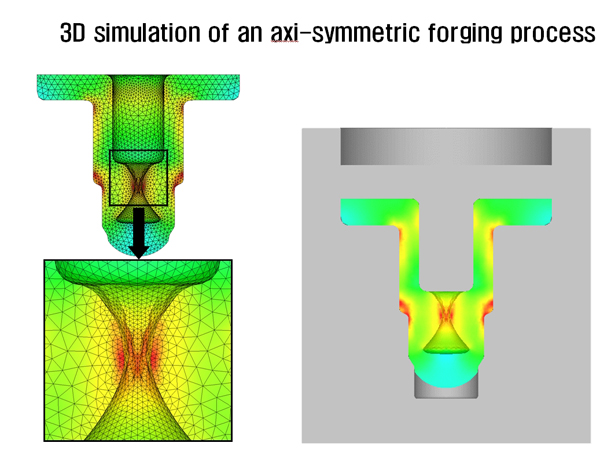

[Hot Forging]3D simulation of an axi-symmetric forging process

An axi-symmetric hot forging process was simulated using a rigid-viscoplastic finite element method. This axi-symmetric process is characterized by three-dimensional material flow near the inner radius due to compressive circumferential stress, which causes a kind of buckling. Mesh system with effective strain is shown in the figure and animation.

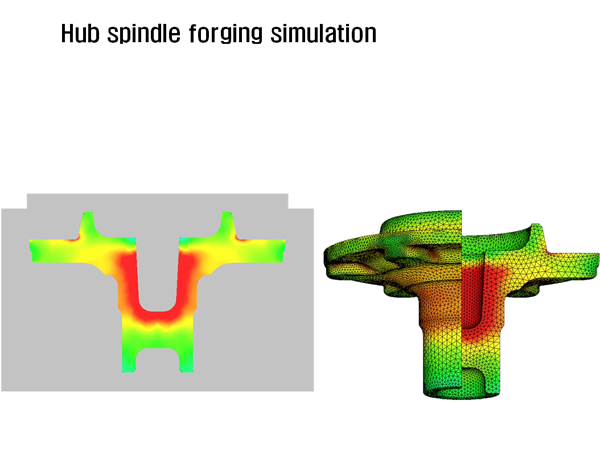

Read More[Hot Forging]Simulation of hub spindle hot forging process

A closed-die forging process without flash was simulated using a rigid-viscoplastic finite element method. The process is characterized by no flash allowed along the interface between the upper and lower dies. Mesh system with effective strain is shown in the figure and animation.

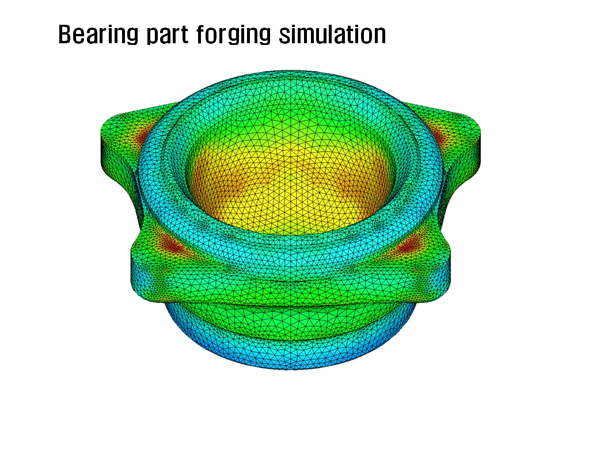

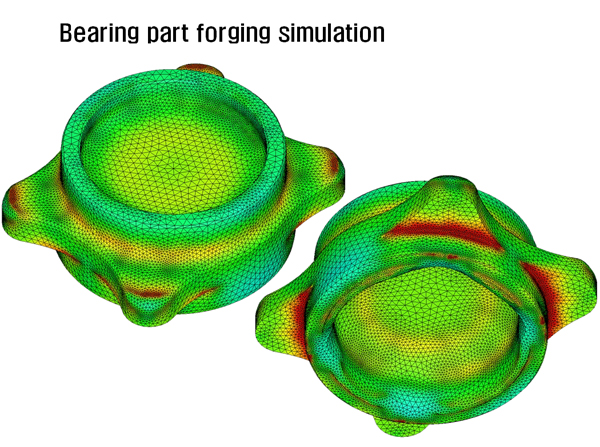

Read More[Hot Forging]Simulation of a bearing part hot forging process

A hot forging process of bearing part with one plane of symmetry was simulated by rigid-viscoplastic finite element method with the intelligent remeshing function. Mesh system with effective strain is shown in the figure and animation.

Read More[Hot Forging]Simulation of a bearing part hot forging process

A hot forging process of bearing part with two planes of symmetry was simulated by rigid-viscoplastic finite element method with the intelligent remeshing function. Mesh system with effective strain is shown in the figure and animation.

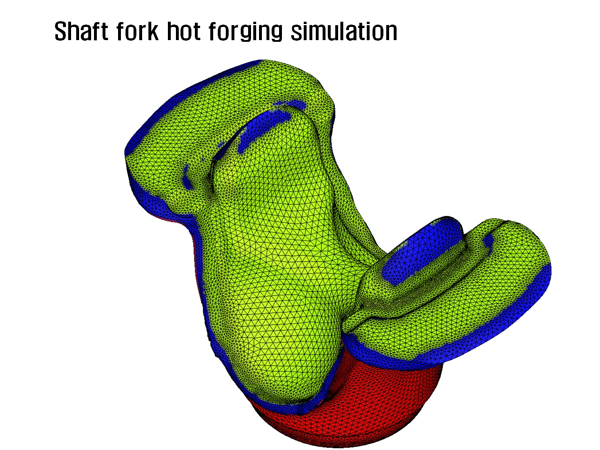

Read More[Hot Forging]Simulation of shaft fork hot forging process

An iso-thermal analysis of a shaft fork hot forging process was conducted. The animation shows the change of contact surface with emphasis on mesh density along the boundaries of the die-material interface. Because metal forming simulation is solving the boundary value problem, the mesh density along the boundaries of the die-material interface is of great…

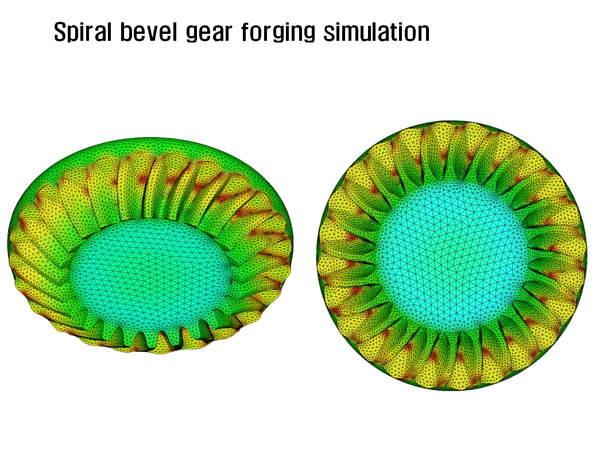

Read More[Cold Forging]Simulation of a spiral bevel gear forging process

A spiral bevel gear forging process was simulated using the intelligent remeshing function. The predictions were shown with emphasis on teeth formation. It can be seen that all teeth were formed with high accuracy even though minimized number of tetrahedral elements was used. Note that too small tetrahedral elements cause frequent remeshings which deteriorate solution…

Read More