article

MFCAE 2019

MFCAE 2019 will be held in Jinju, Korea on August 8 and 9, 2019. With this AFDEX user conference, participants have a chance to share new features and use cases of AFDEX. We welcome you and look forward to your active participation. Location Date City Topic 1 MBC Convention 2019.08.08~09 Jinju New functions, theoretical and…

Read MoreAEPA 2018

MFRC at AEPA 2018, Jeju Island, Republic of Korea http://aepa2018.org/ The 14th Asia – Pacific Symposium on Engineering Plasticity and its applications (AEPA 2018), successfully got over on December 7, 2018 at KAL Hotel Seogwipo, Jeju Island. The conference had a wide variety of presentations, lectures and workshops in the field of metal forming…

Read MoreBauschinger Effect in High-Strength Low-Strain-Hardening Materials – Post [1/2]

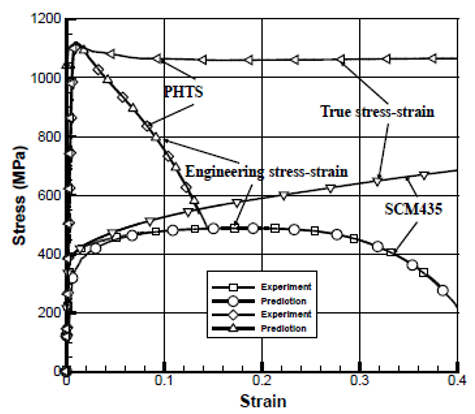

Bauschinger Effect in High-Strength Low-Strain-Hardening Materials – Post [1/2] In a series of 2 posts starting this week, the Bauschinger effect in high strength low-strain-hardening materials will be discussed. 1. Introduction It is noteworthy that cold-forged, high-strength materials or parts can often bypass heat treatment after being formed, which minimizes the amount of post-work due…

Read MoreAFDEX Training Program at Ciudad Juarez

AFDEX Training Program at Ciudad Juarez The developers of AFDEX, the intelligent metal forming simulator, successfully conducted a 1-day training program on the basics of AFDEX and also gave an overview on the advancements in forging simulation technology at Ciudad Juarez City, Mexico on 31st of October 2018. We would like to personally thank each…

Read MoreMexico city training program as it happened

Two-day training program with practice session in Mexico City – In Pictures October 29 and 30, 2018 | 10:00 -16:30 October 29 – Monday – Hotel Camino Real Aeropuerto, Mexico City October 30 – Tuesday – Practice Session at Universidad Politécnica del Valle de México (UPVM), Mexico City The developers of AFDEX, the intelligent metal…

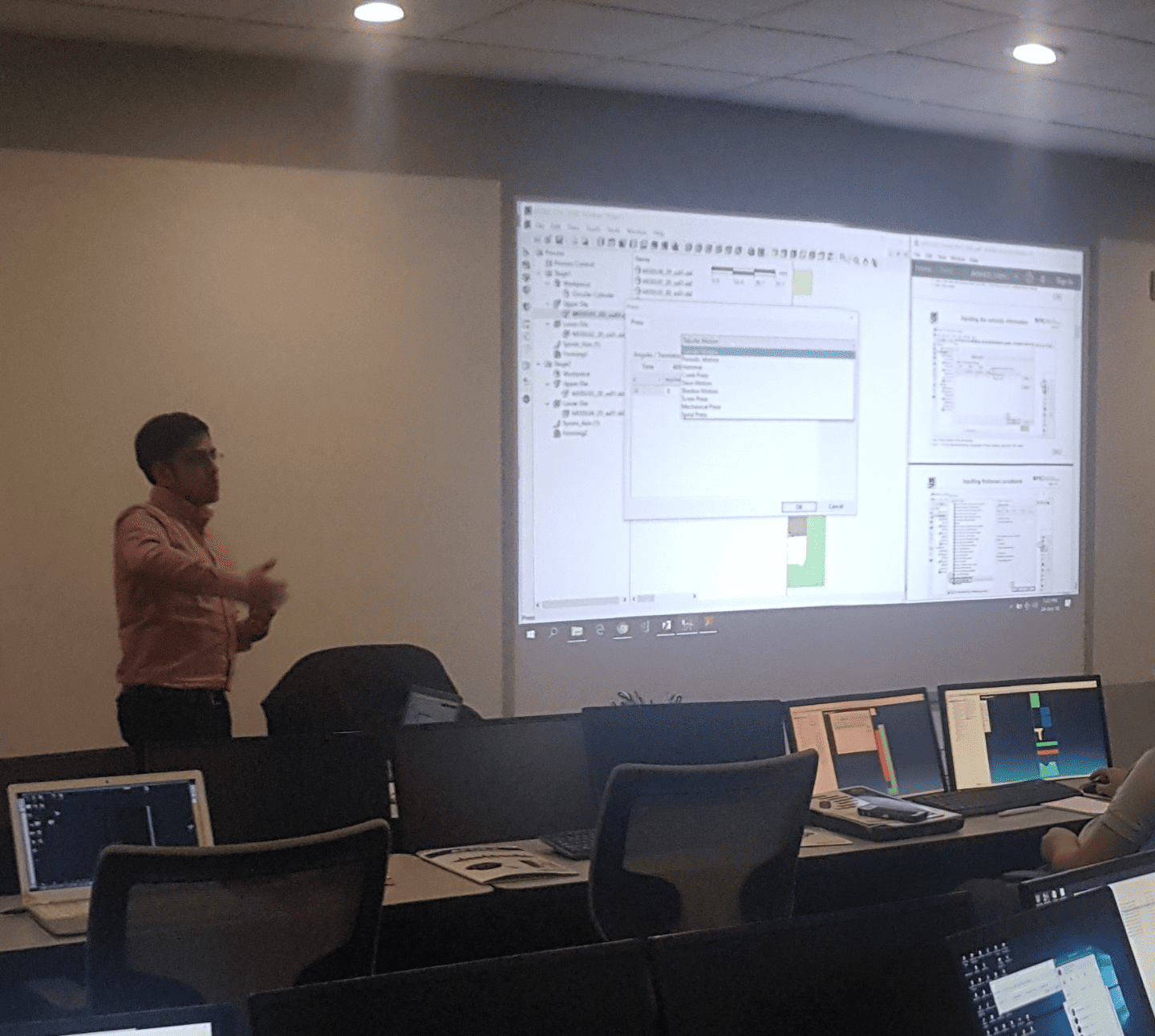

Read MoreAFDEX Training program at Altair Headquarters, USA

2 day AFDEX Training program at Altair Headquarters, USA October 24 and 25, 2018 | 10:00 am – 4:30 pm EDT Altair Engineering Headquarters | 1820 Big Beaver Rd, Troy, MI 48083

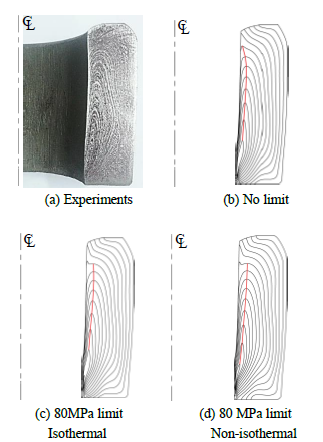

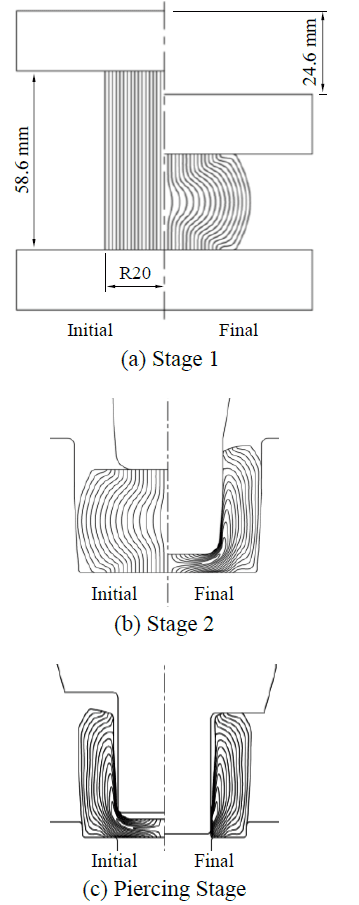

Read MoreEffect of flow stress on finite element predictions of metal flow lines in forging

Effect of flow stress on finite element predictions of metal flow lines in forging In the previous article, it was mentioned that the relatively small dead metal region due to flow stress model employed may cause the difference, which gives us an idea with expectation that a lower limit of flow stress model, i.e., initial…

Read MoreEffect of friction, temperature and velocity on finite element predictions of metal flow lines in forging

Effect of friction, temperature and velocity on finite element predictions of metal flow lines in forging In metal forming, especially in forging, metal flow lines formed during rolling or drawing play decisive role at product strength and integrity [1-4]. Of course, they vary globally with plastic deformation due to metal forming. Therefore, they store the…

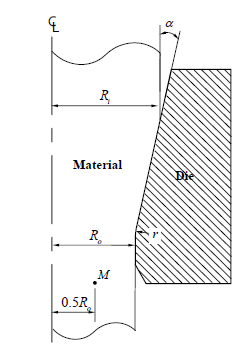

Read MoreFinite element analysis of a tube swaging process

Finite element analysis of a tube swaging process Swaging process is a metal forming process for manufacturing various mechanical parts by changing cross-sections of rods, tubes and wires [1-10]. There are several advantages of the swaging. First, it is advantageous in mass producing straight or tapered metal shapes with various cross-sections including circle, square, gear…

Read MoreComparison of rigid-plastic and elasto-plastic finite element predictions of a tensile test of cylindrical specimens – Post 2

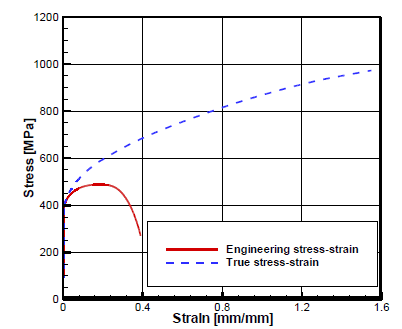

Comparison of rigid-plastic and elasto-plastic finite element predictions of a tensile test of cylindrical specimens – Post 2 In this continuing post, the results of elastoplastic finite element analysis of the tensile test will be presented. The flow stress shown in Fig. 1, obtained by a material identification algorithm based on rigid-plastic finite element method,…

Read MoreComparison of rigid-plastic and elasto-plastic finite element predictions of a tensile test of cylindrical specimens – Post 1

Comparison of rigid-plastic and elasto-plastic finite element predictions of a tensile test of cylindrical specimens – Post 1 Tensile test gives valuable information about finite element analysis and some criterion on its evaluation. It should be noted that tensile test can be not only used for acquisition of flow stress but it can be also…

Read More