article

Metal forming simulation with emphasis on metal flow lines using AFDEX software

Metal forming simulation with emphasis on metal flow lines using AFDEX software There are so many kinds of failures occurring in developing metal forming processes, which are very costly and time-consuming. Under-filling or overlapping defects can be easily removed using the forging simulation software technologies. In many real situations, in fact, those defects can be…

Read MoreMFCAE 2018

MFCAE 2018 was being held in Jinju, Korea on August 16 and 17, 2018. With this AFDEX user conference, participants have a chance to share new features and use cases of AFDEX. Location Date City Topic 1 MBC Convention 2018.08.16~17 Jinju New functions, theoretical and practical examples

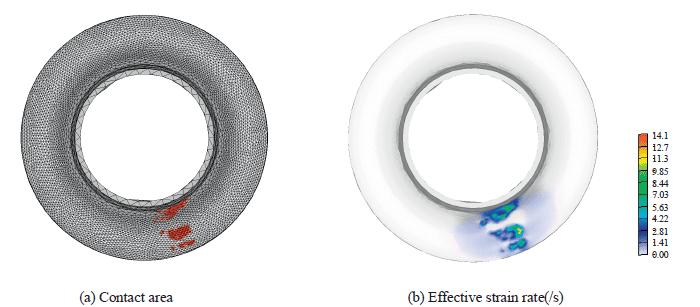

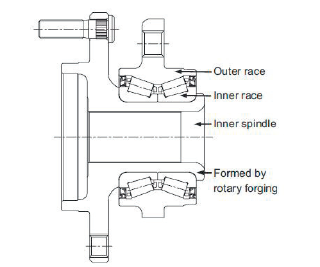

Read MoreFinite element analysis model of rotary forging for assembling wheel hub bearing assembly – Post 2

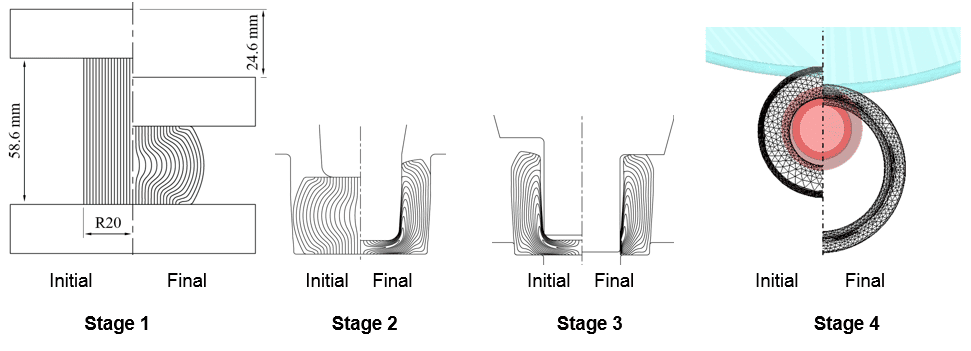

Finite element analysis model of rotary forging for assembling wheel hubbearing assembly – Post 2/2 This post is in continuation with last week’s post on the finite element analysis model of rotary forging process of a wheel hub bearing assembly. Adding on to that introductory post, the details of the analysis model and the predictions…

Read MoreFinite element analysis model of rotary forging for assembling wheel hub bearing assembly – Post 1

Finite element analysis model of rotary forging for assemblingwheel hub bearing assembly – Post 1 This topic will be covered under a series of posts starting from this week. In the past the wheel hub bearing assembly was assembled by incredible methods which were much dependent on the manual experience. Thus, the tolerance changed from…

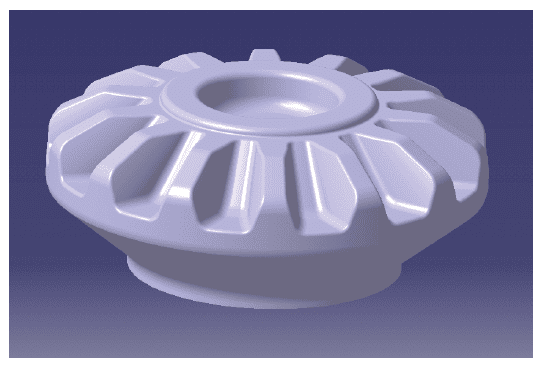

Read MoreEnclosed die forging of an automobile differential’s bevel gear – Post 2/2

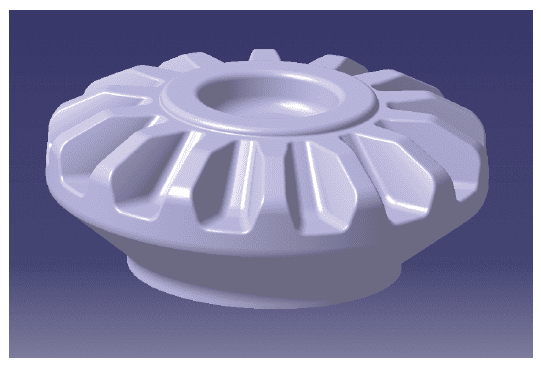

Enclosed die forging of an automobile differential’s bevel gear – Post 2/2 This article is a continuation to the earlier article – http://www.afdex.com/archive/blog/4 In this article, we will go further into the results and discuss this approach from a manufacturing perspective. Just a recap of the important information. The material of the bevel gear is SCM420H…

Read MoreAutomatic simulation of multistage cold-forging process

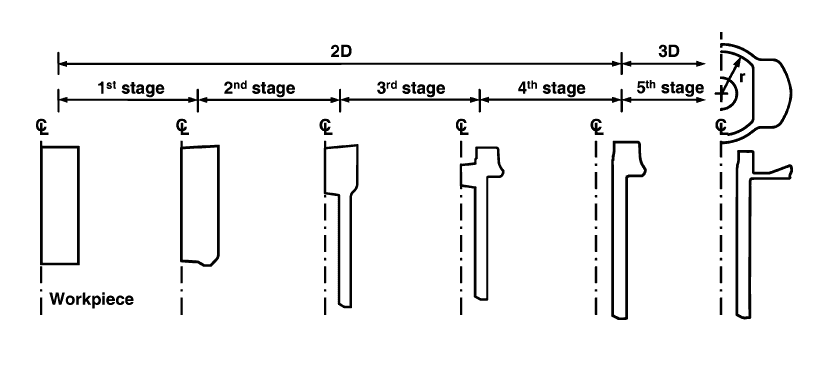

Automatic and precise simulation of multistage automatic cold-forging processes by combined analyses of two- and three-dimensional approaches A five-stage cold-forging sequence is selected as a representative example of multistage automatic forging processes because it has four axisymmetric forging stages followed by a non-axisymmetric forging stage and involves piercing and heading processes accompanying folding and overlapping.…

Read MoreEnclosed die forging of an automobile differential’s bevel gear – Post 1/2

Enclosed die forging of an automobile differential’s bevel gear – Post 1/2 If the production of smaller size bevel gears is carried out by the closed forging method, it is advantageous in terms of quality and price. This is because the process is minimalistic and raw materials are reduced. And it has a longer die…

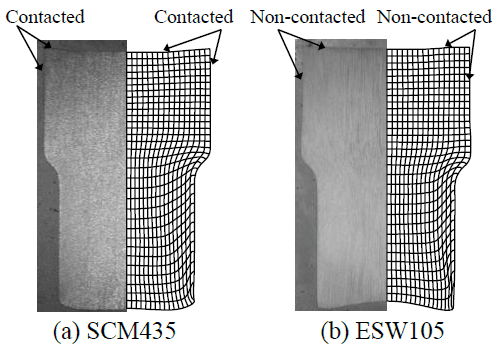

Read MoreConsideration on metal flow lines in forging and their prediction in ring rolling after forging

Consideration on metal flow lines in forging and their prediction in ring rolling after forging Metal flow lines (MFLs) or fiber flow lines are one of major factors affecting product liability and structural rigidity. It is thus essential to test the MFLs of a forging to evaluate its soundness in terms of metal forming because…

Read MoreFinite element analysis of deep piercing process

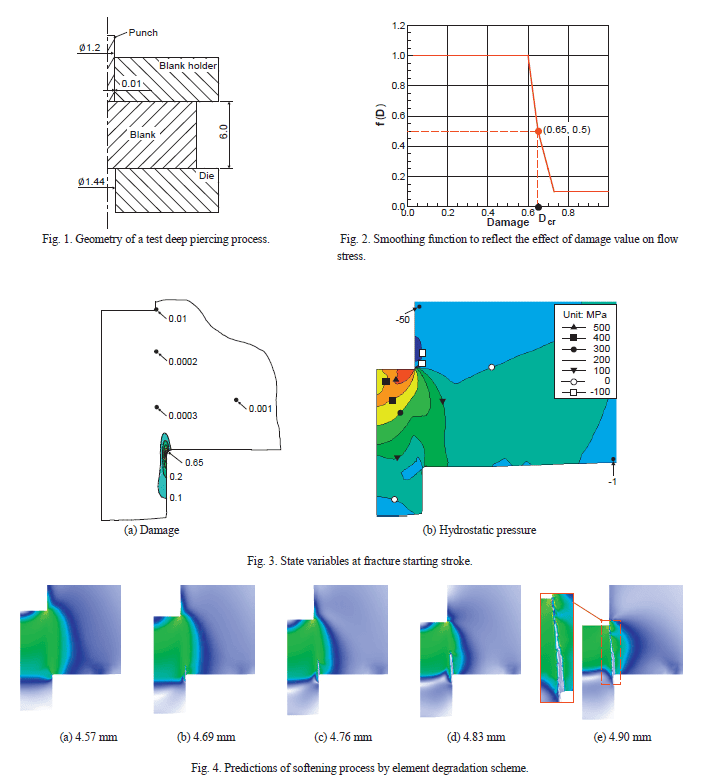

Finite element analysis of deep piercing process Aspect ratio, in the case of piercing in metal forming is the ratio between the thickness and the hole diameter which is usually ranges between 1.0 and 1.5. In the case of deep piercing processes, the aspect ratio goes up to 5. This is challenging from the perspective…

Read MoreHannover Messe 2018

Hannover Messe, the world’s leading industrial show, covers all the core areas of industry – R&D, Automation and IT, Industrial Supply, Production Technology and Services as well as Energy and Mobility Technology. http://www.hannovermesse.de/exhibitor/MFRC/X553779 MFRC would like to participate in this year’s Hannover Messe. We are excited to meet and network with the forging fraternity. If…

Read MoreDevelopers’ Meeting

1. 2017 The first Developers’ Meeting in 2017 was held on Jan. 6, 2017 followed by two conferences at the Korean Society of Technology of Plasticity and one at the user conference, i.e., MFCAE 2017. 2. 2018 On December 28, 2017, the AFDEX Developers’ Meeting of 2018 was held at MFRC’s new office (Rm. 1207-1209,…

Read MoreInternship with Universiti Teknologi Mara

The internship program was held from 17th Jul. to 15th Sep. 2017. It has been tailored to prepare engineering graduates become competent mechanical engineers. The interns have been exposed to the metal forming processes and systems which includes comprehensive AFDEX, CATIA, AutoCAD software training and its application for forging industries. Thank you.

Read More